Overview

Midwest Tube Mills manufacturers steel tubing for a wide variety of mechanical applications. Our tubing is made to the highest quality standards. All of our products deliver consistent quality and long-term strength and reliability.

- Greenhouses

- Dairy

- Playgrounds

- Vehicle Frames/Trailers

- Agriculture

- Solar

- Metal & Fabric Structures

- Conveyor Systems

Square Tubing is available in gauges ranging from 12 to 18 with sizes ranging from 2” to 2.50”Rectangular Tubing is available in gauges from 12 to 18 with sizes ranging from 1” x 2” to 2” x 3”Swaging -MTM offers swaging on 1.315”, 1.660” and 1.900” O.D. tubing. Swaging eliminates the need for tube fitting, reduces the opportunity for leaks while increasing the I.D. of the tubing.Notching/Coping - on 1.315” tubing for perfect fittings and weldments.Custom Cut-to-Length - for O.D.s from 1.315” to 2.875.”O.D. Finishing - MTM can provide polishing and sanding on O.D.s of all round tubing and powder coating on all mechanical products.

Sizes Available

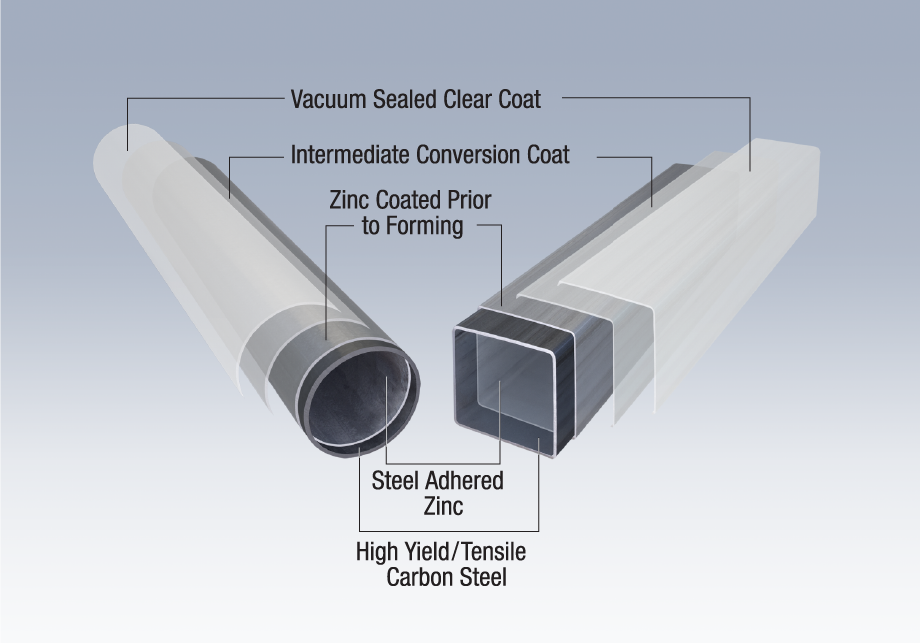

Diagram