MT 40 is manufactured utilizing our new state-of-the-art process that produces pipe that exceeds strict industry standards and easily outperforms Schedule 40 pipe in both strength and corrosion resistance and in-line galvanized pipe in salt spray tests.

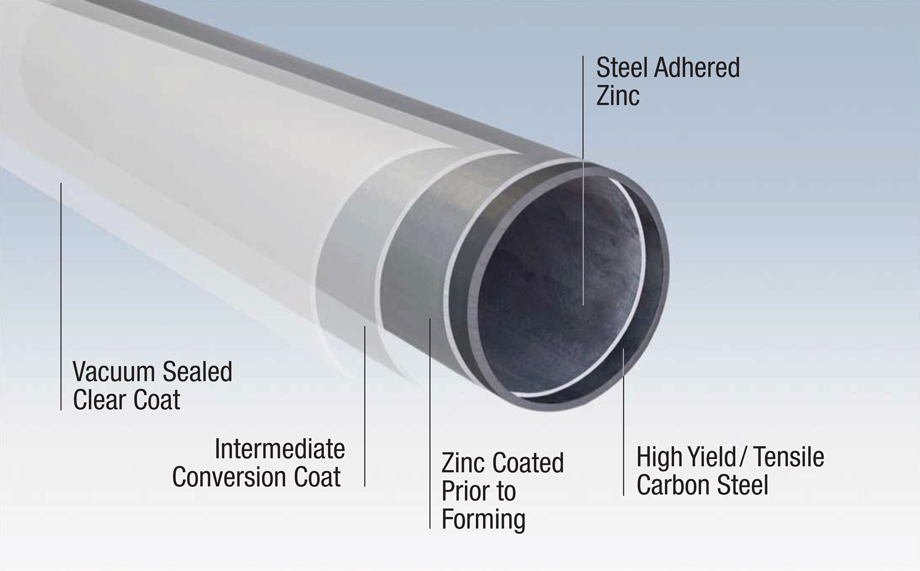

Manufacturing Process - MT 40 is manufactured using hot rolled steel. A triple layer

of OD corrosion protection consisting of a steel-adhered zinc bath, an intermediate

conversion coat and a clear vacuum sealed top coat is then added to provide the maximum

in protection and durability. The ID is zinc coated prior to forming.

High Yield Strength 50,000 PSI Steel - and triple coat protection results in pipe

that is lighter and outperforms Schedule 40 in strength and corrosion resistance.This

unique process means that MT 40 is 37% stronger and 21% lighter than Schedule 40

tubing.

- Specifications

- F-162 Federal Aviation

- M-181 AASHTO

- UFGS 02821 (supercedes CEGS 02821)

- NFGS 02831 Dept. of the Navy

- RR F-191 Chain Link Fence Specification

- ASTM A513

- ASTM A500 Grade B

- 50,000 Yield

- ASTM F-1043 Group IC, IC-L

Made in U.S.A. - All MT 40 product from Midwest Tube Mills is manufactured in the

USA and is in compliance with federal, state and local specifications. We meet Buy

America(n) requirements.